Experienced Manufacturers

Production plant area of more than 10,000 square feet, more than 100 people construction team.

Hotline

Hotline

Industry introduction

The competitive situation of the century's oceans is more severe, and our country is facing new challenges in the process of the development of the marine economy, and at the same time, new opportunities have emerged. We need to understand what factors are limiting the development of China's oceans, and under the development of new industries, the marine industry will inevitably diversify. Ships and related engineering facilities are the important carrier and material embodiment of whether the marine development strategy can be effectively implemented, and the marine development strategy affects the direction of ship development at the same time.

Pollution Hazard

In the ship R & D and manufacturing production process will inevitably produce organic pollution, common cutter, injection moulding, welding, painting and other positions is the existence of certain volatile organic compounds, such exhaust gas such as not into the collection and treatment of the post will cause some physical harm to employees.

Overview of the treatment programme

For shipbuilding VOCs management technology, now in line with environmental emission requirements, and play a cost-effective management technology, is the use of combustion method of management technology is more economical and energy-saving and effective. Wet jet washing (multi-pipe) + dry filter + wind reduction and thickening + catalytic combustion combination of governance, governance can meet the emission requirements

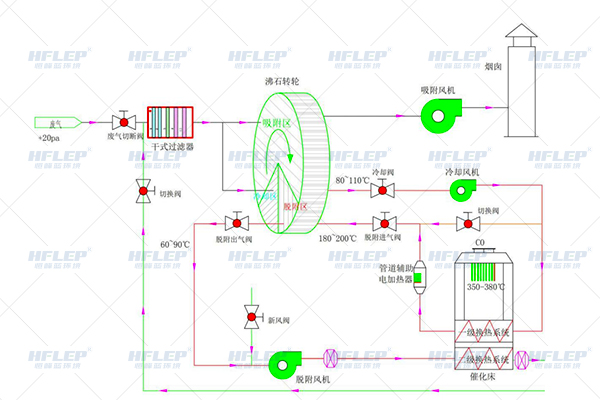

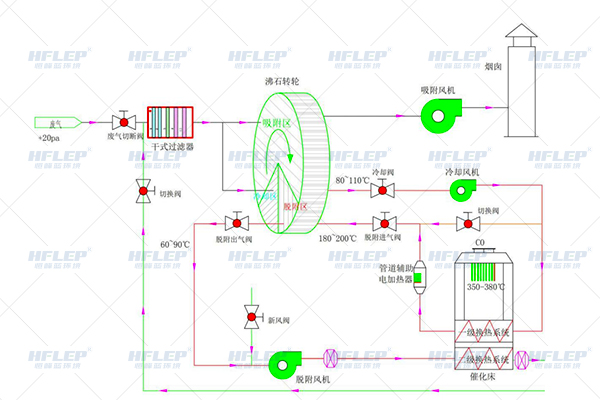

Process flow

Shipbuilding waste gas treatment adopts wet jet washing (multi-pipe) + dry filtration + zeolite rotor adsorption concentration + catalytic combustion process (integrated system) process treatment. Organic waste gas is collected through the pipeline and enters the pretreatment wet jet tower to remove the paint dew, acidity and particulate matter purification. After purification, the gas is introduced into the dry filter to remove particles and zeolite adsorption of hazardous substances, and the organic waste gas is then sent to the zeolite adsorption bed device, and the VOCs in the waste gas is absorbed by the zeolite and then discharged to the atmosphere in compliance with the standards.

When the zeolite adsorption bed is saturated by electric heating at high temperature (100-180 ℃ C) desorption of VOCs substances, desorption of high concentrations of organic waste gas directly into the catalytic combustion co, through the accelerated oxidation of high concentrations of waste gas by precious metals, in ( 250-380 ℃) high temperature purification and oxidation of harmless carbon dioxide (CO2) and water vapour (H20) and discharge to the atmosphere to meet the standards.

Other treatment technology programmes

Low concentration and small air volume shipbuilding waste gas can be used: spray tower, uv photolysis purifier, activated carbon adsorption and other single or multiple combinations of processes for treatment;

High concentration of small air volume shipbuilding waste gas can be used: pretreatment + zeolite molecular sieve + catalytic combustion, pretreatment + zeolite molecular sieve + RTO thermal storage incinerator, a single catalytic combustion device or a single RTO thermal storage incinerator and so on;

High concentration and large air volume shipbuilding waste gas can be used: pretreatment + zeolite rotor concentration + catalytic combustion or pretreatment + zeolite rotor concentration + RTO thermal storage incinerator and so on.

Reason for choice

Production plant area of more than 10,000 square feet, more than 100 people construction team.

A number of engineers and technicians, most of whom have more than 10 years of experience and have worked on numerous projects.

Adoption of the latest domestic and international treatment technology, with high treatment efficiency.

According to the actual needs of the project, free to customise the corresponding exhaust gas treatment solutions, all regions of the country package to meet the emission standards.

Passed the third level of construction enterprise qualification and a number of technical patents...

1000+ project experience, more than 100 industry partners, complete environmental protection qualification.

Contact - Ways

Contact information

Catalytic combustion machine is a dry filter + adsorption de...

Activated carbon adsorption and desorption + CO catalytic co...

Zeolite rotor concentration + RTO regenerative incinerator c...

Zeolite rotor concentration + CO catalytic combustion proces...

CO catalytic combustion + TO direct combustion furnace proce...

For low concentration and low air volume of waste gas treatm...

Industry introduction

The competitive situation of the century's oceans is more severe, and our country is facing new challenges in the process of the development of the marine economy, and at the same time, new opportunities have emerged. We need to understand what factors are limiting the development of China's oceans, and under the development of new industries, the marine industry will inevitably diversify. Ships and related engineering facilities are the important carrier and material embodiment of whether the marine development strategy can be effectively implemented, and the marine development strategy affects the direction of ship development at the same time.

Pollution Hazard

In the ship R & D and manufacturing production process will inevitably produce organic pollution, common cutter, injection moulding, welding, painting and other positions is the existence of certain volatile organic compounds, such exhaust gas such as not into the collection and treatment of the post will cause some physical harm to employees.

Overview of the treatment programme

For shipbuilding VOCs management technology, now in line with environmental emission requirements, and play a cost-effective management technology, is the use of combustion method of management technology is more economical and energy-saving and effective. Wet jet washing (multi-pipe) + dry filter + wind reduction and thickening + catalytic combustion combination of governance, governance can meet the emission requirements

Process flow

Shipbuilding waste gas treatment adopts wet jet washing (multi-pipe) + dry filtration + zeolite rotor adsorption concentration + catalytic combustion process (integrated system) process treatment. Organic waste gas is collected through the pipeline and enters the pretreatment wet jet tower to remove the paint dew, acidity and particulate matter purification. After purification, the gas is introduced into the dry filter to remove particles and zeolite adsorption of hazardous substances, and the organic waste gas is then sent to the zeolite adsorption bed device, and the VOCs in the waste gas is absorbed by the zeolite and then discharged to the atmosphere in compliance with the standards.

When the zeolite adsorption bed is saturated by electric heating at high temperature (100-180 ℃ C) desorption of VOCs substances, desorption of high concentrations of organic waste gas directly into the catalytic combustion co, through the accelerated oxidation of high concentrations of waste gas by precious metals, in ( 250-380 ℃) high temperature purification and oxidation of harmless carbon dioxide (CO2) and water vapour (H20) and discharge to the atmosphere to meet the standards.

Other treatment technology programmes

Low concentration and small air volume shipbuilding waste gas can be used: spray tower, uv photolysis purifier, activated carbon adsorption and other single or multiple combinations of processes for treatment;

High concentration of small air volume shipbuilding waste gas can be used: pretreatment + zeolite molecular sieve + catalytic combustion, pretreatment + zeolite molecular sieve + RTO thermal storage incinerator, a single catalytic combustion device or a single RTO thermal storage incinerator and so on;

High concentration and large air volume shipbuilding waste gas can be used: pretreatment + zeolite rotor concentration + catalytic combustion or pretreatment + zeolite rotor concentration + RTO thermal storage incinerator and so on.