Experienced Manufacturers

Production plant area of more than 10,000 square feet, more than 100 people construction team.

Hotline

Hotline

Industry introduction

The development of fine chemical industry promotes other industries such as agriculture, medicine, textile printing and dyeing, leather, paper and other clothing, food, travel and use of the level of improvement, and at the same time for these industries to bring about an increase in economic benefits. The development of fine chemicals for biotechnology, information technology, new materials, new energy technology, environmental protection and other high-tech development to provide a guarantee. Directly for the production and processing of petroleum and petrochemical three major synthetic materials (plastics, rubber and fibre), the production of agricultural chemicals, providing catalysts, auxiliaries, special gases, special materials (anti-corrosion, high temperature, solvent-resistant), flame retardant, membrane materials, a variety of additives, industrial surfactants, environmental protection and governance of the chemicals to ensure and promote the development of the petroleum and chemical industries.

Pollution hazards

Fine chemical production process will produce toxic substances, such as in the biomass boiler operation, salt evaporation process, liquid chlorine vaporisation, class A workshop, pyrazole naphthylamine, laboratory workshop and so on, the operation of the post will produce volatile organic waste gas, this kind of waste gas has a high degree of toxicity, such as after the collection of the treatment of the human eyes, skin and mucous membranes and the respiratory tract will have a strong irritating effect. Inhalation may result in death due to spasm of the larynx and bronchial tubes, oedema, inflammation, chemical pneumonitis and pulmonary oedema.

Overview of the treatment programme

Fine chemical waste gas VOCs treatment technology, now in line with environmental emission requirements, and play a cost-effective treatment technology, for the production line of the reaction tank centrifuge, recovery tower fine tower, fixed top, salt evaporation workshop, the methyl to extract and recycle non-halogenated organic waste gas produced by the laboratory of organic waste gas, it is the use of two-stage condensation method + two acid / alkali + a level of absorption + + + regenerative thermal incinerator RTO + a level of alkali absorption + a level of water absorption treatment technology more than ever. Absorption + a water absorption treatment technology is more economical and energy-saving, after the treatment can meet the emission requirements of the standard!

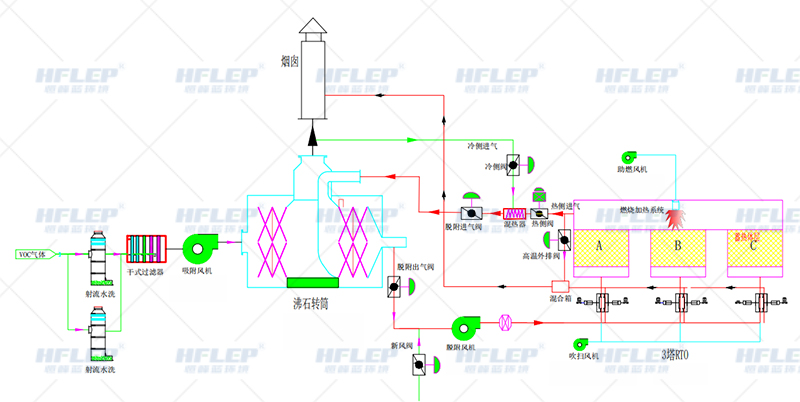

Process flow

Other treatment process technology

Low concentration and small air volume of fine chemical waste gas can be used: spray tower, uv photolysis purifier, activated carbon adsorption and other single or multiple combinations of processes for treatment;

High concentration of small air volume of fine chemical waste gas can be used: pretreatment + zeolite molecular sieve + catalytic combustion; pretreatment + zeolite molecular sieve + RTO thermal storage incinerator, a single catalytic combustion device or a single RTO thermal storage incinerator and so on;

High concentration and large air volume of fine chemical waste gas can be used: pretreatment + zeolite rotor concentration + catalytic combustion or pretreatment + zeolite rotor concentration + RTO thermal storage incinerator and so on.

Reason for choice

Production plant area of more than 10,000 square feet, more than 100 people construction team.

A number of engineers and technicians, most of whom have more than 10 years of experience and have worked on numerous projects.

Adoption of the latest domestic and international treatment technology, with high treatment efficiency.

According to the actual needs of the project, free to customise the corresponding exhaust gas treatment solutions, all regions of the country package to meet the emission standards.

Passed the third level of construction enterprise qualification and a number of technical patents...

1000+ project experience, more than 100 industry partners, complete environmental protection qualification.

Contact - Ways

Contact information

Catalytic combustion machine is a dry filter + adsorption de...

Activated carbon adsorption and desorption + CO catalytic co...

Zeolite rotor concentration + RTO regenerative incinerator c...

Zeolite rotor concentration + CO catalytic combustion proces...

CO catalytic combustion + TO direct combustion furnace proce...

For low concentration and low air volume of waste gas treatm...

Industry introduction

The development of fine chemical industry promotes other industries such as agriculture, medicine, textile printing and dyeing, leather, paper and other clothing, food, travel and use of the level of improvement, and at the same time for these industries to bring about an increase in economic benefits. The development of fine chemicals for biotechnology, information technology, new materials, new energy technology, environmental protection and other high-tech development to provide a guarantee. Directly for the production and processing of petroleum and petrochemical three major synthetic materials (plastics, rubber and fibre), the production of agricultural chemicals, providing catalysts, auxiliaries, special gases, special materials (anti-corrosion, high temperature, solvent-resistant), flame retardant, membrane materials, a variety of additives, industrial surfactants, environmental protection and governance of the chemicals to ensure and promote the development of the petroleum and chemical industries.

Pollution hazards

Fine chemical production process will produce toxic substances, such as in the biomass boiler operation, salt evaporation process, liquid chlorine vaporisation, class A workshop, pyrazole naphthylamine, laboratory workshop and so on, the operation of the post will produce volatile organic waste gas, this kind of waste gas has a high degree of toxicity, such as after the collection of the treatment of the human eyes, skin and mucous membranes and the respiratory tract will have a strong irritating effect. Inhalation may result in death due to spasm of the larynx and bronchial tubes, oedema, inflammation, chemical pneumonitis and pulmonary oedema.

Overview of the treatment programme

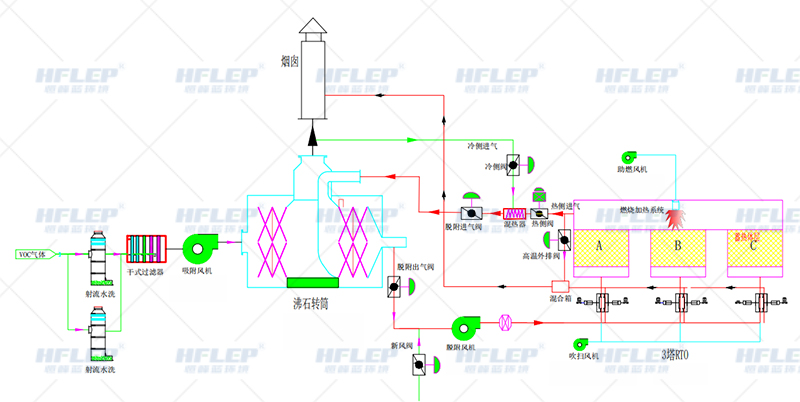

Fine chemical waste gas VOCs treatment technology, now in line with environmental emission requirements, and play a cost-effective treatment technology, for the production line of the reaction tank centrifuge, recovery tower fine tower, fixed top, salt evaporation workshop, the methyl to extract and recycle non-halogenated organic waste gas produced by the laboratory of organic waste gas, it is the use of two-stage condensation method + two acid / alkali + a level of absorption + + + regenerative thermal incinerator RTO + a level of alkali absorption + a level of water absorption treatment technology more than ever. Absorption + a water absorption treatment technology is more economical and energy-saving, after the treatment can meet the emission requirements of the standard!

Process flow

Other treatment process technology

Low concentration and small air volume of fine chemical waste gas can be used: spray tower, uv photolysis purifier, activated carbon adsorption and other single or multiple combinations of processes for treatment;

High concentration of small air volume of fine chemical waste gas can be used: pretreatment + zeolite molecular sieve + catalytic combustion; pretreatment + zeolite molecular sieve + RTO thermal storage incinerator, a single catalytic combustion device or a single RTO thermal storage incinerator and so on;

High concentration and large air volume of fine chemical waste gas can be used: pretreatment + zeolite rotor concentration + catalytic combustion or pretreatment + zeolite rotor concentration + RTO thermal storage incinerator and so on.