Experienced Manufacturers

Production plant area of more than 10,000 square feet, more than 100 people construction team.

Hotline

Hotline

Flexible Packaging Printing Industry Introduction

Flexible packaging printing technology is the use of ink, adhesives, solvents after modulation into the required colour, colour printing in the handheld paper bags, corrugated cardboard boxes, paper boxes, envelopes, trademarks, fragile packaging, beverage flexible packages, food packaging and other packaging printing technology. Through the technology of the flexible packaging printing industry, the printing machine used for gravure printing as well as dry laminating machine, flexible packaging is also known as & ldquo; flexographic printing & rdquo;. Therefore, flexible packaging printing industry technology involves a very wide range of industries.

Flexible packaging printing pollution hazards

As flexible packaging printing is used to use ink, adhesives, solvents in the modulation and drying process generates organic emissions, according to the flexible packaging printing industry volatile organic compounds statistics flexible packaging printing industry VOCs emissions of about 1 to 2 million tonnes / year, of which VOCs emissions from the flexible packaging industry accounted for 60% to 70%, about 700,000 to 1.2 million tonnes / year, so the flexible packaging printing industry exhaust gas Therefore, the exhaust gas from the flexible packaging printing industry will cause great harm to the human body, and even cause dermatitis, damage to the nervous system and so on.

Flexible Packaging Printing Solution Overview

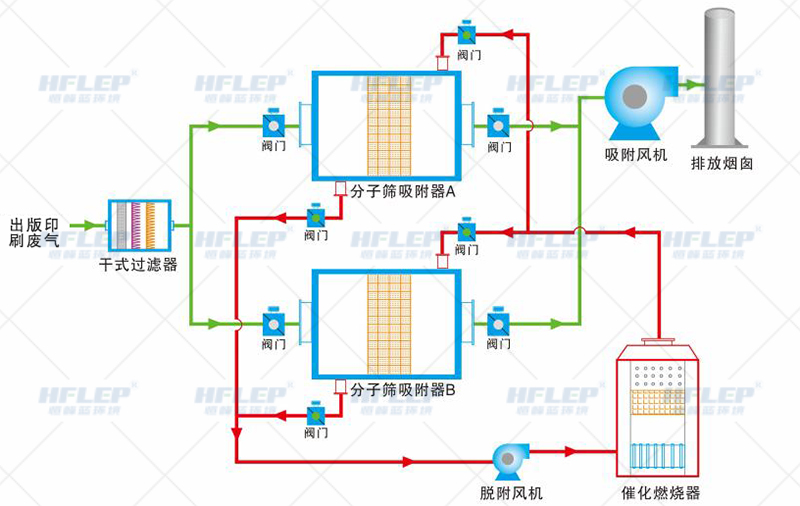

For the flexible packaging printing industry VOCs management technology, now in line with environmental emission requirements, and play a cost-effective management technology, is the use of combustion method of management technology is more economical and energy efficient. The use of dry filters + reduced wind concentration + catalytic combustion combination of governance, governance can meet the emission requirements of the standard!

Flexible Packaging Printing Treatment Process

This device process is: first through the three-stage dry filter to remove 99% of the particles in the dusty gas, so that the organic matter is completely clean, but also to increase the operating efficiency and service life of the late equipment. Separation of organic gases into the zeolite turn concentration or molecular sieve adsorption concentration of organic waste gas low concentration into high concentration, large air volume conversion of small air volume to reduce the principle of concentration, when the adsorption concentration reaches the required spontaneous combustion requirements, and finally through electric heating to warm up the high temperature of 100-180 degrees Celsius gas, desorption regeneration, desorption of down the use of catalytic furnace of the high concentration of catalytic furnace, with the help of catalysts to make the organic waste gas in the lower starting temperature for flameless combustion, so that the late equipment operating efficiency and service life. With the help of catalyst, the organic waste gas will be flamelessly burned under lower ignition temperature, so that the organic waste gas will be decomposed into non-toxic carbon dioxide and water vapour.

Other treatment process technology

Low concentration and small air volume of flexible packaging printing waste gas can be used: spray tower, uv photolysis purifier, activated carbon adsorption and other single or multiple combinations of processes for treatment;

High concentration of small air volume of flexible packaging printing waste gas can be used: pretreatment + zeolite molecular sieve + catalytic combustion, pretreatment + zeolite molecular sieve + RTO thermal storage incinerator, a single catalytic combustion device or a single RTO thermal storage incinerator and so on;

High concentration and large air volume of flexible packaging printing waste gas can be used: pretreatment + zeolite rotor concentration + catalytic combustion or pretreatment + zeolite rotor concentration + RTO thermal storage incinerator and so on.

Reason for choice

Production plant area of more than 10,000 square feet, more than 100 people construction team.

A number of engineers and technicians, most of whom have more than 10 years of experience and have worked on numerous projects.

Adoption of the latest domestic and international treatment technology, with high treatment efficiency.

According to the actual needs of the project, free to customise the corresponding exhaust gas treatment solutions, all regions of the country package to meet the emission standards.

Passed the third level of construction enterprise qualification and a number of technical patents...

1000+ project experience, more than 100 industry partners, complete environmental protection qualification.

Contact - Ways

Contact information

Catalytic combustion machine is a dry filter + adsorption de...

Activated carbon adsorption and desorption + CO catalytic co...

Zeolite rotor concentration + RTO regenerative incinerator c...

Zeolite rotor concentration + CO catalytic combustion proces...

CO catalytic combustion + TO direct combustion furnace proce...

For low concentration and low air volume of waste gas treatm...

Flexible Packaging Printing Industry Introduction

Flexible packaging printing technology is the use of ink, adhesives, solvents after modulation into the required colour, colour printing in the handheld paper bags, corrugated cardboard boxes, paper boxes, envelopes, trademarks, fragile packaging, beverage flexible packages, food packaging and other packaging printing technology. Through the technology of the flexible packaging printing industry, the printing machine used for gravure printing as well as dry laminating machine, flexible packaging is also known as & ldquo; flexographic printing & rdquo;. Therefore, flexible packaging printing industry technology involves a very wide range of industries.

Flexible packaging printing pollution hazards

As flexible packaging printing is used to use ink, adhesives, solvents in the modulation and drying process generates organic emissions, according to the flexible packaging printing industry volatile organic compounds statistics flexible packaging printing industry VOCs emissions of about 1 to 2 million tonnes / year, of which VOCs emissions from the flexible packaging industry accounted for 60% to 70%, about 700,000 to 1.2 million tonnes / year, so the flexible packaging printing industry exhaust gas Therefore, the exhaust gas from the flexible packaging printing industry will cause great harm to the human body, and even cause dermatitis, damage to the nervous system and so on.

Flexible Packaging Printing Solution Overview

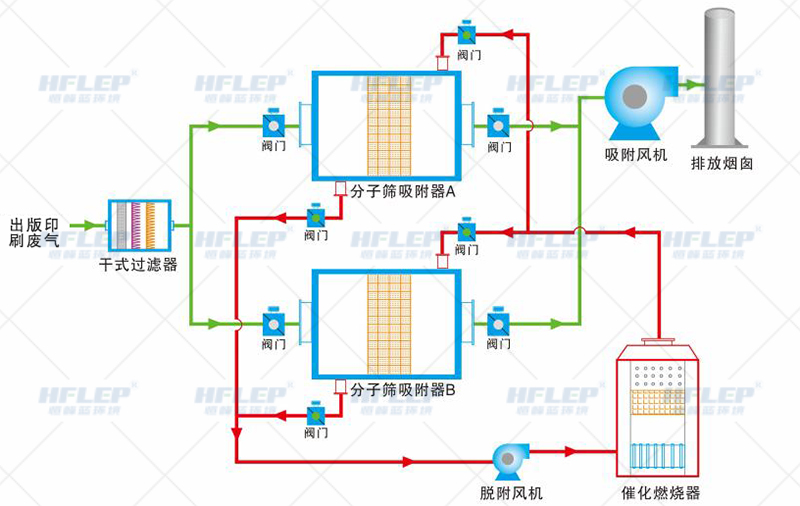

For the flexible packaging printing industry VOCs management technology, now in line with environmental emission requirements, and play a cost-effective management technology, is the use of combustion method of management technology is more economical and energy efficient. The use of dry filters + reduced wind concentration + catalytic combustion combination of governance, governance can meet the emission requirements of the standard!

Flexible Packaging Printing Treatment Process

This device process is: first through the three-stage dry filter to remove 99% of the particles in the dusty gas, so that the organic matter is completely clean, but also to increase the operating efficiency and service life of the late equipment. Separation of organic gases into the zeolite turn concentration or molecular sieve adsorption concentration of organic waste gas low concentration into high concentration, large air volume conversion of small air volume to reduce the principle of concentration, when the adsorption concentration reaches the required spontaneous combustion requirements, and finally through electric heating to warm up the high temperature of 100-180 degrees Celsius gas, desorption regeneration, desorption of down the use of catalytic furnace of the high concentration of catalytic furnace, with the help of catalysts to make the organic waste gas in the lower starting temperature for flameless combustion, so that the late equipment operating efficiency and service life. With the help of catalyst, the organic waste gas will be flamelessly burned under lower ignition temperature, so that the organic waste gas will be decomposed into non-toxic carbon dioxide and water vapour.

Other treatment process technology

Low concentration and small air volume of flexible packaging printing waste gas can be used: spray tower, uv photolysis purifier, activated carbon adsorption and other single or multiple combinations of processes for treatment;

High concentration of small air volume of flexible packaging printing waste gas can be used: pretreatment + zeolite molecular sieve + catalytic combustion, pretreatment + zeolite molecular sieve + RTO thermal storage incinerator, a single catalytic combustion device or a single RTO thermal storage incinerator and so on;

High concentration and large air volume of flexible packaging printing waste gas can be used: pretreatment + zeolite rotor concentration + catalytic combustion or pretreatment + zeolite rotor concentration + RTO thermal storage incinerator and so on.