Experienced Manufacturers

Production plant area of more than 10,000 square feet, more than 100 people construction team.

Hotline

Hotline

Industry introduction

Pesticide industry and pharmaceutical industry is closely related to the pesticide industry is currently the world's unified English name pesticide— a that is & ldquo; killing agents & rdquo;; but in fact the so-called pesticide refers to be used to prevent and control harmful to agriculture, forestry and animal husbandry production of harmful organisms (pests, pest mites, nematodes, pathogenic fungi, weeds and rodents. Later, through the longer-term development of the production and life process, gradually recognised that some natural has the performance of the prevention and control of harmful organisms in agriculture and animal husbandry. To 17 categories, etc.) and regulating plant growth of chemicals and biological drugs. Usually used for hygiene and improve the physical and chemical properties of the active ingredients of various additives are also included.

Pollution hazards

Pesticide industry in the production process will produce a certain amount of organic waste gas pollution, and the nature of pollution and its seriousness. In each of the different types of workshops in the production process of organic substances such as: cyclohexane, isopropanol, triethylamine, xylene, ethylene dichloride, ethanol, methyl chloroformate, toluene, phenyl isocyanate, m-tolyl isocyanate, ethyl formate, morpholine, CS2, ethyl acetate, n-hexane, dimethyl sulphate, sulfonyl chloride, and other organic components of the exhaust gas.

Overview of the treatment programme

Pesticide industry exhaust VOCs management technology, now in line with environmental emission requirements, and play a cost-effective management technology, for the fine chemical waste gas does not contain halogenated organic waste gas through the second level of condensation + second level of acid / alkali neutralisation and absorption + first level of water absorption + regenerative incinerator RTO + first level of alkali absorption + first level of water absorption + 30 m exhaust emissions, containing halogenated organic exhaust through the second level of condensation + second level of alkali absorption + first level of water absorption + biofilter + second level of water absorption + first level of water absorption + biological filtration tanks. The halogenated organic waste gas is discharged through secondary condensation + secondary alkali absorption + primary water absorption + biofilter + 30 metres exhaust pipe, which can meet the emission requirement standard after treatment!

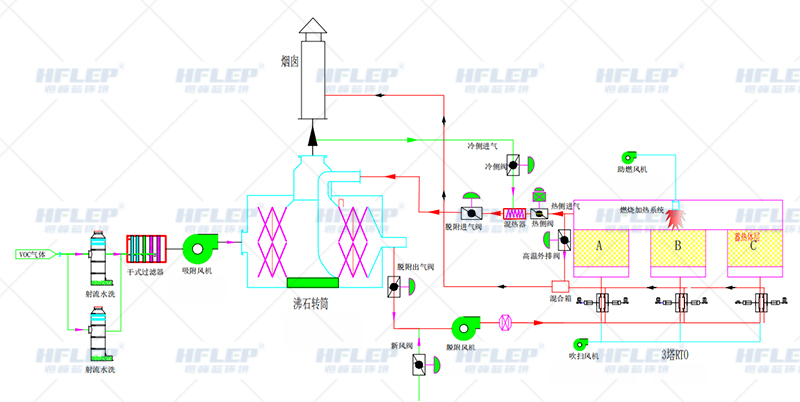

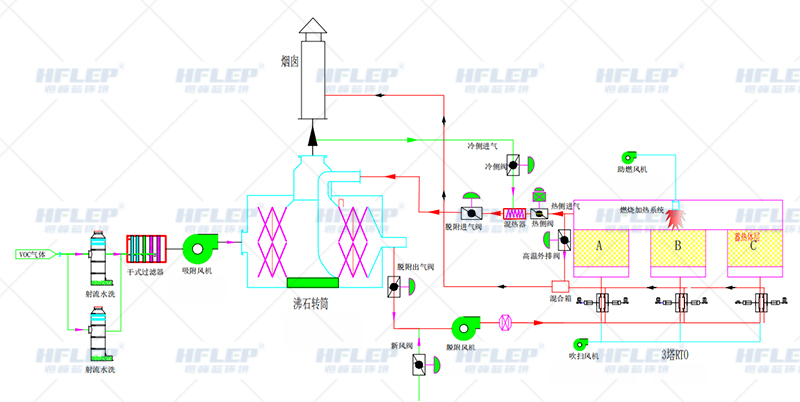

Process flow

Other treatment process technology

Low concentration and small air volume of pesticide industry exhaust gas can be used: spray tower, uv photolysis purifier, activated carbon adsorption and other single or multiple combinations of processes for treatment;

High concentration of small air volume of pesticide industry exhaust can be used: pretreatment + zeolite molecular sieve + catalytic combustion; pretreatment + zeolite molecular sieve + RTO thermal storage incinerator, a single catalytic combustion device or a single RTO thermal storage incinerator and so on;

High concentration and large air volume of pesticide industry waste gas can be used: pretreatment + zeolite rotor concentration + catalytic combustion or pretreatment + zeolite rotor concentration + RTO thermal storage incinerator and so on.

Reason for choice

Production plant area of more than 10,000 square feet, more than 100 people construction team.

A number of engineers and technicians, most of whom have more than 10 years of experience and have worked on numerous projects.

Adoption of the latest domestic and international treatment technology, with high treatment efficiency.

According to the actual needs of the project, free to customise the corresponding exhaust gas treatment solutions, all regions of the country package to meet the emission standards.

Passed the third level of construction enterprise qualification and a number of technical patents...

1000+ project experience, more than 100 industry partners, complete environmental protection qualification.

Contact - Ways

Contact information

Catalytic combustion machine is a dry filter + adsorption de...

Activated carbon adsorption and desorption + CO catalytic co...

Zeolite rotor concentration + RTO regenerative incinerator c...

Zeolite rotor concentration + CO catalytic combustion proces...

CO catalytic combustion + TO direct combustion furnace proce...

For low concentration and low air volume of waste gas treatm...

Industry introduction

Pesticide industry and pharmaceutical industry is closely related to the pesticide industry is currently the world's unified English name pesticide— a that is & ldquo; killing agents & rdquo;; but in fact the so-called pesticide refers to be used to prevent and control harmful to agriculture, forestry and animal husbandry production of harmful organisms (pests, pest mites, nematodes, pathogenic fungi, weeds and rodents. Later, through the longer-term development of the production and life process, gradually recognised that some natural has the performance of the prevention and control of harmful organisms in agriculture and animal husbandry. To 17 categories, etc.) and regulating plant growth of chemicals and biological drugs. Usually used for hygiene and improve the physical and chemical properties of the active ingredients of various additives are also included.

Pollution hazards

Pesticide industry in the production process will produce a certain amount of organic waste gas pollution, and the nature of pollution and its seriousness. In each of the different types of workshops in the production process of organic substances such as: cyclohexane, isopropanol, triethylamine, xylene, ethylene dichloride, ethanol, methyl chloroformate, toluene, phenyl isocyanate, m-tolyl isocyanate, ethyl formate, morpholine, CS2, ethyl acetate, n-hexane, dimethyl sulphate, sulfonyl chloride, and other organic components of the exhaust gas.

Overview of the treatment programme

Pesticide industry exhaust VOCs management technology, now in line with environmental emission requirements, and play a cost-effective management technology, for the fine chemical waste gas does not contain halogenated organic waste gas through the second level of condensation + second level of acid / alkali neutralisation and absorption + first level of water absorption + regenerative incinerator RTO + first level of alkali absorption + first level of water absorption + 30 m exhaust emissions, containing halogenated organic exhaust through the second level of condensation + second level of alkali absorption + first level of water absorption + biofilter + second level of water absorption + first level of water absorption + biological filtration tanks. The halogenated organic waste gas is discharged through secondary condensation + secondary alkali absorption + primary water absorption + biofilter + 30 metres exhaust pipe, which can meet the emission requirement standard after treatment!

Process flow

Other treatment process technology

Low concentration and small air volume of pesticide industry exhaust gas can be used: spray tower, uv photolysis purifier, activated carbon adsorption and other single or multiple combinations of processes for treatment;

High concentration of small air volume of pesticide industry exhaust can be used: pretreatment + zeolite molecular sieve + catalytic combustion; pretreatment + zeolite molecular sieve + RTO thermal storage incinerator, a single catalytic combustion device or a single RTO thermal storage incinerator and so on;

High concentration and large air volume of pesticide industry waste gas can be used: pretreatment + zeolite rotor concentration + catalytic combustion or pretreatment + zeolite rotor concentration + RTO thermal storage incinerator and so on.