Experienced Manufacturers

Production plant area of more than 10,000 square feet, more than 100 people construction team.

Hotline

Hotline

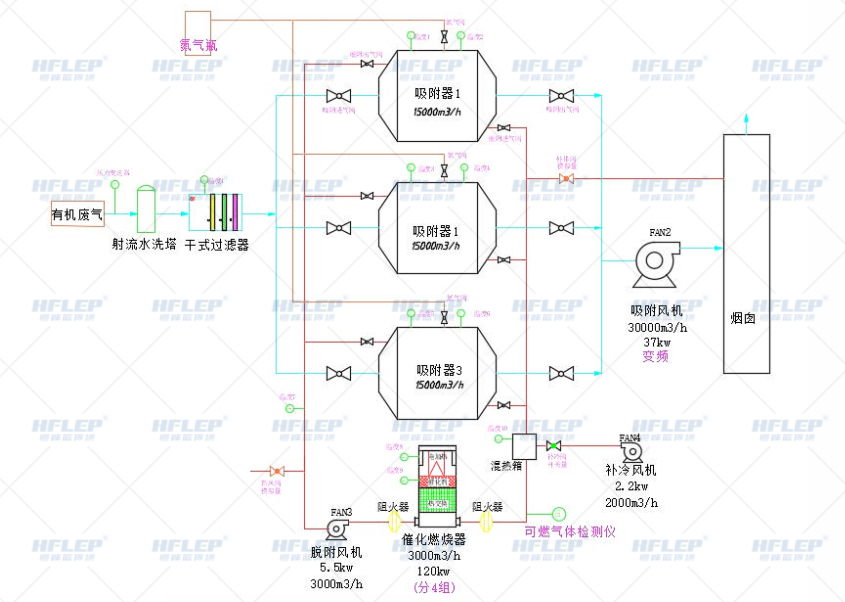

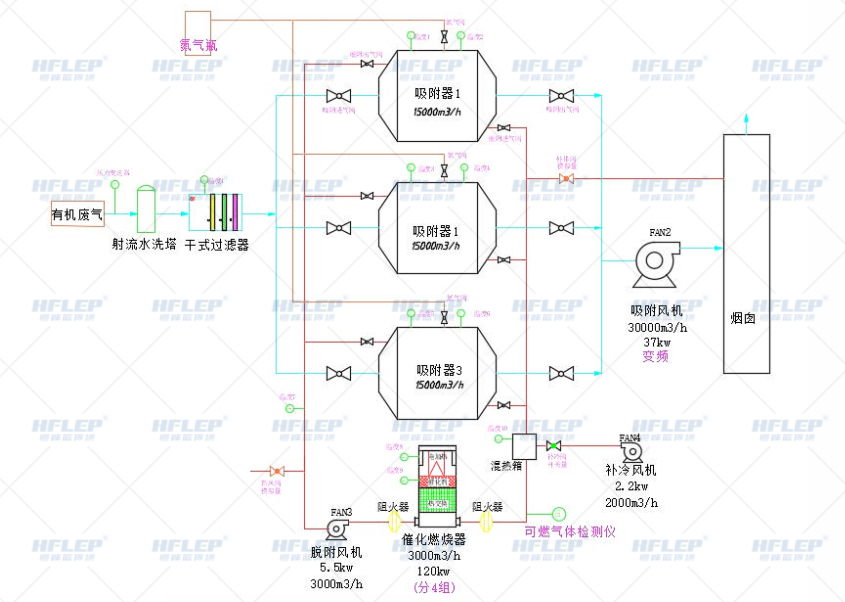

Sheet metal factory paint exhaust treatment process flow

Other treatment process technology

Reason for choice

Production plant area of more than 10,000 square feet, more than 100 people construction team.

A number of engineers and technicians, most of whom have more than 10 years of experience and have worked on numerous projects.

Adoption of the latest domestic and international treatment technology, with high treatment efficiency.

According to the actual needs of the project, free to customise the corresponding exhaust gas treatment solutions, all regions of the country package to meet the emission standards.

Passed the third level of construction enterprise qualification and a number of technical patents...

1000+ project experience, more than 100 industry partners, complete environmental protection qualification.

Contact - Ways

Contact information

Catalytic combustion machine is a dry filter + adsorption de...

Activated carbon adsorption and desorption + CO catalytic co...

Zeolite rotor concentration + RTO regenerative incinerator c...

Zeolite rotor concentration + CO catalytic combustion proces...

CO catalytic combustion + TO direct combustion furnace proce...

For low concentration and low air volume of waste gas treatm...

Sheet metal factory paint exhaust treatment process flow

Other treatment process technology