Experienced Manufacturers

Production plant area of more than 10,000 square feet, more than 100 people construction team.

Hotline

Hotline

Industry Introduction

Since the 1980s, domestic construction steel structure has seen unprecedented development, with high-rise steel structure, space steel structure, bridge steel structure, lightweight steel structure and residential steel structure springing up. Welding, as a main connection method for building steel structure, has been developing rapidly in physics, chemistry, metallurgy, materials, electronics, computers, automatic control and other disciplines, and plays a more important role in the construction of steel structure of buildings in China with the continuous emergence of new technologies, new materials, new equipments, and new techniques. According to statistics, about more than 50 per cent of steel needs to be processed by welding before being put into use. Therefore, the improvement of welding level is the key to realise the rapid development of steel structure technology and ensure the quality of building steel structure construction.

Pollution Hazard

Commonly used methods for welding of building steel structure mainly include manual electric arc welding, gas shielded welding, self-protected electric arc welding, submerged arc welding, and so on. These processes produce particles, as well as harmful gases during operation, and the high-temperature welding process usually produces ozone, nitrogen oxides, carbon monoxide, fluoride and chloride. Without collecting and treating the exhaust gases, long term operation will be hazardous to the health of the welders, including: pneumoconiosis, manganese poisoning, fluorine poisoning, metal fume fever and electro-optical ophthalmia.

Overview of the treatment programme

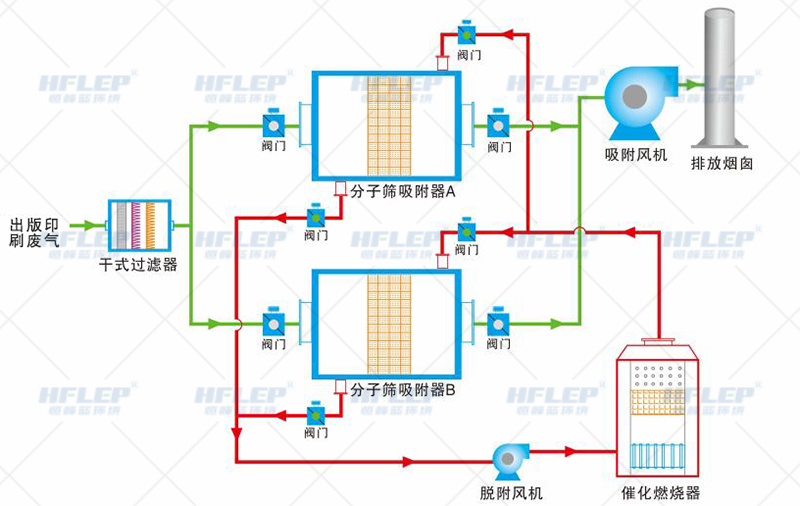

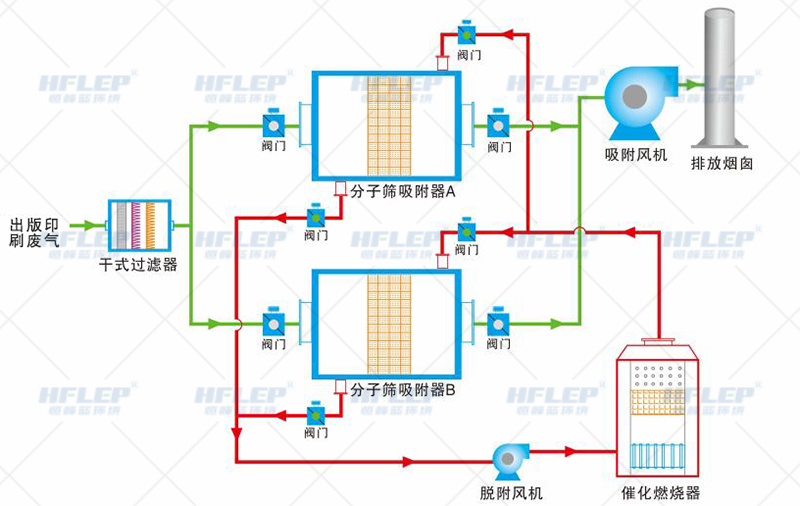

For the construction of steel structure welding industry VOCs treatment technology, now in line with environmental emission requirements, and play a role in reducing the cost and efficiency of the treatment technology, is to use combustion method of treatment technology is more economical and energy-saving effective. Adopting dry filter + wind reduction and thickening + catalytic combustion combination of governance, governance can meet the emission requirements of the standard!

Process flow

Five building steel welding exhaust gas treatment first through the three-stage dry filter, removing 99% of the particles in the dusty gas, so that the organic matter is completely clean, but also to increase the later equipment operating efficiency and service life. Separated organic gas into the zeolite to concentrate or molecular sieve adsorption concentration, the organic waste gas low concentration into high concentration, large air volume conversion of small air volume to reduce the wind concentration principle.

When the adsorption concentration reaches the required self-combustion requirements, and finally through electric heating to warm up the high temperature gas of 80-100 degrees for desorption and regeneration, desorption down to the high concentration of the use of CO catalytic furnace, with the help of catalysts to make the organic waste gas in the lower temperature of ignition under the flameless combustion, so that the organic exhaust decomposition of carbon dioxide and water vapour into non-toxic.

Other treatment technology programmes

Low concentration and small air volume construction steel welding exhaust gas can be used: spray tower, uv photolysis purifier, activated carbon adsorption and other single or multiple combinations of processes for treatment;

High concentration of small air volume construction steel welding exhaust gas can be used: pretreatment + zeolite molecular sieve + catalytic combustion, pretreatment + zeolite molecular sieve + RTO thermal storage incinerator, a single catalytic combustion device or a single RTO thermal storage incinerator and so on;

High concentration and large air volume building steel welding exhaust gas can be used: pretreatment + zeolite rotor concentration + catalytic combustion or pretreatment + zeolite rotor concentration + RTO thermal storage incinerator and so on.

Reason for choice

Production plant area of more than 10,000 square feet, more than 100 people construction team.

A number of engineers and technicians, most of whom have more than 10 years of experience and have worked on numerous projects.

Adoption of the latest domestic and international treatment technology, with high treatment efficiency.

According to the actual needs of the project, free to customise the corresponding exhaust gas treatment solutions, all regions of the country package to meet the emission standards.

Passed the third level of construction enterprise qualification and a number of technical patents...

1000+ project experience, more than 100 industry partners, complete environmental protection qualification.

Contact - Ways

Contact information

Catalytic combustion machine is a dry filter + adsorption de...

Activated carbon adsorption and desorption + CO catalytic co...

Zeolite rotor concentration + RTO regenerative incinerator c...

Zeolite rotor concentration + CO catalytic combustion proces...

CO catalytic combustion + TO direct combustion furnace proce...

For low concentration and low air volume of waste gas treatm...

Industry Introduction

Since the 1980s, domestic construction steel structure has seen unprecedented development, with high-rise steel structure, space steel structure, bridge steel structure, lightweight steel structure and residential steel structure springing up. Welding, as a main connection method for building steel structure, has been developing rapidly in physics, chemistry, metallurgy, materials, electronics, computers, automatic control and other disciplines, and plays a more important role in the construction of steel structure of buildings in China with the continuous emergence of new technologies, new materials, new equipments, and new techniques. According to statistics, about more than 50 per cent of steel needs to be processed by welding before being put into use. Therefore, the improvement of welding level is the key to realise the rapid development of steel structure technology and ensure the quality of building steel structure construction.

Pollution Hazard

Commonly used methods for welding of building steel structure mainly include manual electric arc welding, gas shielded welding, self-protected electric arc welding, submerged arc welding, and so on. These processes produce particles, as well as harmful gases during operation, and the high-temperature welding process usually produces ozone, nitrogen oxides, carbon monoxide, fluoride and chloride. Without collecting and treating the exhaust gases, long term operation will be hazardous to the health of the welders, including: pneumoconiosis, manganese poisoning, fluorine poisoning, metal fume fever and electro-optical ophthalmia.

Overview of the treatment programme

For the construction of steel structure welding industry VOCs treatment technology, now in line with environmental emission requirements, and play a role in reducing the cost and efficiency of the treatment technology, is to use combustion method of treatment technology is more economical and energy-saving effective. Adopting dry filter + wind reduction and thickening + catalytic combustion combination of governance, governance can meet the emission requirements of the standard!

Process flow

Five building steel welding exhaust gas treatment first through the three-stage dry filter, removing 99% of the particles in the dusty gas, so that the organic matter is completely clean, but also to increase the later equipment operating efficiency and service life. Separated organic gas into the zeolite to concentrate or molecular sieve adsorption concentration, the organic waste gas low concentration into high concentration, large air volume conversion of small air volume to reduce the wind concentration principle.

When the adsorption concentration reaches the required self-combustion requirements, and finally through electric heating to warm up the high temperature gas of 80-100 degrees for desorption and regeneration, desorption down to the high concentration of the use of CO catalytic furnace, with the help of catalysts to make the organic waste gas in the lower temperature of ignition under the flameless combustion, so that the organic exhaust decomposition of carbon dioxide and water vapour into non-toxic.

Other treatment technology programmes

Low concentration and small air volume construction steel welding exhaust gas can be used: spray tower, uv photolysis purifier, activated carbon adsorption and other single or multiple combinations of processes for treatment;

High concentration of small air volume construction steel welding exhaust gas can be used: pretreatment + zeolite molecular sieve + catalytic combustion, pretreatment + zeolite molecular sieve + RTO thermal storage incinerator, a single catalytic combustion device or a single RTO thermal storage incinerator and so on;

High concentration and large air volume building steel welding exhaust gas can be used: pretreatment + zeolite rotor concentration + catalytic combustion or pretreatment + zeolite rotor concentration + RTO thermal storage incinerator and so on.